Hot charging of billet and slab

Reduce Energy Costs, Increase Productivity & Reduce Carbon Emissions

Background

Iron and steelmaking currently account for 7% of world CO2 production. Reduction of carbon emissions from steel manufacturing processes is therefore a global imperative.

The largest sources of steel industry carbon emissions are in the primary plants. These convert raw materials to semi-finished products – slabs and billets. Replacement of Blast Furnaces with a DRI route will be required to achieve carbon emission targets. Such fundamental changes are extremely large scale and highly capital intensive.

Emissions from natural gas fired reheat furnaces in hot rolling mills are a lesser but still significant carbon source. In this case, there is potential to substantially reduce the emissions with relatively small process changes – and to simultaneously achieve other major benefits.

Specifically, hot charging of slabs or billets into reheating furnaces while they still retain heat from casting is a way to reduce fuel consumption – thereby decreasing both carbon emissions and manufacturing cost. In addition, hot charging increases the output of furnaces – which are often rate limiting in hot rolling mills.

The scale of this opportunity is illustrated by Erdemir in Turkey who reported saving USD $13 million per year as a result hot charging 50 % of slabs.

Introduction

Slabs and billets leave continuous casters at a temperature suitable for hot rolling - between 1200 and 1250 C.

Fig 1: Hot slabs immediately after casting.

In many cases however, the newly-cast slabs are allowed to become completely cold – then require reheating in natural gas fired furnaces prior to hot rolling.

Such re-heating of slabs and billets generates a significant amount of CO2. Reported quantities vary, but 70 kg of CO2 per ton of rolled steel is a reasonable indicative number.

Fuel consumed reheating slabs and billets is a major element in the cost of hot rolling. Also, reheating of slabs often limits hot rolling mill output – at least for the wider part of the product mix.

The above issues make it highly desirable to link the caster directly to the hot rolling mill via a roller table. In this case the only furnace required is a small device for heat holding and temperature adjustment. This is now an established technology in hot rolling mills making simple commodity products.

However, hot rolling mills making advanced automotive products are never directly linked to a caster. A proportion of their slabs may be hot charged into furnaces while they still retain about 50% of the heat from casting – but at present benefits from this are limited.

This page outlines why direct rolling in commodity product mills is possible – and explains the complex issues which limit hot charging of automotive products. Based on this, strategies for increasing hot charging and maximizing its benefits are considered.

Hot / Direct Charging in Rolling Mills Making Commodity Products

Commodity products are generic materials, used on a large scale in common applications such as cladding of buildings. They have simple steel chemistries, basic mechanical properties, and slab widths are mostly in a narrow range – from about 900mm to 1,250mm.

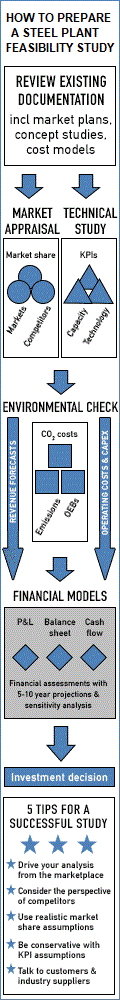

In the case of new-build Hot Strip Mills making commodity products, slabs from a caster can be directly supplied via a heat holding furnace into a hot rolling mill. This Compact Strip Process – referred to as CSP - was pioneered in 1990 by Nucor Crawfordsville.

Fig 2: CSP process route: direct supply of hot slabs from caster into hot rolling.

The above process is viable because, in this case, casting can be matched with the production sequence of the rolling mill.

This is in part due to the limited number of similar carbon steel grades involved. Chemistry ranges for these grades may overlap – and even if they do not, there may still be outlets for slabs produced during caster grade changes. In addition, hot mill scheduling rules for these products are not demanding – and the limited number / range of product widths also help.

The CSP process has another important feature which reduces (electrical) energy consumption and plant cost. It uses thin slabs – which are about one quarter the thickness of conventional 200 mm slabs. This decreases the number of rolling stands required - and eliminates consumption of electricity otherwise incurred there.

Sales of generic commodity products are largely based on price - and direct hot charging greatly reduces fuel cost - a major expense in hot rolling. This provides a compelling commercial motive to adopt the practice.

Rod and bar mills have been slower in pursuing such energy saving technologies. However, their products are also relatively simple – and if casting and rolling are in suitable proximity, there is no technical reason the two processes should not be linked. In this case it might also be possible to utilize a thinner billet approach to achieve benefits like those obtained from thin slabs in CSP mills.

There remain some older hot strip mills making mostly commodity products, which do not have a CSP design / layout. If their caster is located within a few kilometers, it should be possible to rail transport slabs and charge them into reheat furnaces while they still retain significant heat. This requires co-ordination between the caster and hot rolling mill – plus some equipment items and procedures for heat retention. This equipment situation is similar to that which exists when hot charging in automotive hot rolling mills (see below).

Hot Charging in Hot Mills Making Advanced Automotive Products

Fig 3: Most hot mills making automotive products reheat slabs that have cooled during transport and storage.

Automotive materials have been at the leading edge of advanced product development for the last 20 years. This is in part driven by a continuing need to decrease vehicle weight – to reduce fuel consumption and consequent carbon emissions. At the same time, improving “crashworthiness” requires increased energy absorption in frame structures, and extreme high strength of the “safety cage” surrounding the passenger cabin. Finally, exposed body panels require very high formability – and exceptional surface quality for aesthetic reasons.

The term Automotive therefore covers a very wide range of high technology products – which have little in common except for being used in some part of a vehicle.

The size and importance of the automotive market is evidenced by a sizable number of steel manufacturers who invest billions of dollars in hot rolling mills, coupled pickle line / cold mills and galvanizing lines all specifically designed for these products.

Automotive customers are extremely demanding of product quality and on-time delivery – and they pay a premium price for this.

Consistently meeting Automotive customer requirements is therefore essential for survival and is always a primary focus. Cost reductions and productivity increases through hot charging are desirable – but only after the primary quality / delivery objective has been reliably assured.

Hot rolling mills making automotive products have production schedules in the region of 8 to 10 hours. These extend from one change of mill work rolls to the next. Usually a schedule starts narrow, rapidly increases to maximum width, and then slowly narrows down.

Various automotive products are made in specific parts of these schedules. For example, coils for exposed body panels are rolled soon after the start – where their high surface quality requirement fits with work rolls being in the best possible condition. Also, exposed body panel products are mostly wide – and mill schedules usually reach maximum width within about two hours.

Casters have production sequences which are much longer than hot mills. They require days to cycle through a full range of automotive products. This duration is driven by minimizing product losses associated with chemical grade changes, and by width change limitations.

So, with automotive products, caster output cannot be synchronized with the production sequence required by the hot strip mill – and direct linking of casting with hot rolling is not possible.

However, it is still possible to hot charge some slabs into rolling mill reheat furnaces. A challenging goal for such hot charging is to have 50 % of slabs entering hot mill furnaces at a temperature of 650 to 700 centigrade.

Such hot charging typically starts with transporting slabs from the caster using covered rail wagons. Procedures for slab stacking on the rail wagons are also important for heat retention. When slabs arrive in the hot mill slab yard, they are placed in covered pits lined with insulating refractory. In this way, slabs can be kept reasonably hot for several days – before being inserted into a hot mill schedule at an appropriate location.

Operating in this mode requires continuous communication and co-ordination between caster and hot mill scheduling.

Covered rail transport equipment and insulated storage pits have a capital cost. Also, caster transfer tables and shipping areas may not be designed for rapid transit or for fast dispatch of slabs while they still retain as much heat as possible.

Finally, hot charging incurs operational costs. For example, removal and replacement of insulating covers substantially increases the number of crane lifts – requiring crane operator time and increasing crane maintenance needs.

Conditions Required for Maximum Benefit

It is a common misconception that simply putting a few hot slabs into a furnace is sufficient to save fuel. Actually, the benefit in this case is usually impossible to detect.

Hot charging decreases fuel use largely by reducing heating time – making it possible to heat more slabs (or billets) per hour – without a corresponding increase in fuel consumed. So, as well as getting hot slabs into the furnace, we also need to extract and roll them at a faster pace. Achieving a major fuel saving therefore requires the rolling mill to be capable of out-pacing cold charged furnaces. This is usually the case – at least over the wider part of the product range.

It follows that hot charging improvements usually also increase productivity of the hot mill. This can provide substantial financial benefits – above those achieved from reduced fuel consumption.

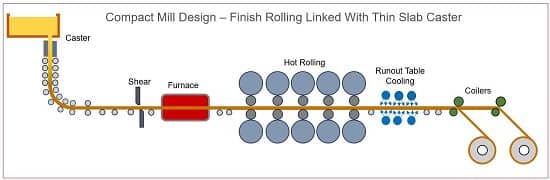

Fig 4: Furnace retention time versus slab charging temperature.

Calculations made by the control model of an actual hot strip mill reheat furnace are shown in Figure 4 above. The vertical axis shows the slab charging temperature. The horizontal axis indicates furnace residence time required for slabs to reach a (typical) discharge temperature of 1250 C.

When slabs enter the reheat furnace at 110 C, required heating time is 135 minutes. When slabs enter at 700 C, heating time reduces to 105 minutes. This represents a 28 % increase in furnace productivity. (Note that achieving this productivity increase requires ALL slabs to be charged at the above defined temperature – This is explained below).

Literature sources indicate that a 100 C increase in slab entry temperature results in a fuel energy saving of 0.086 MMBTU per ton. Increasing slab temperature entering the furnace from 100 to 700 C will therefore save 0.52 MMBTU / ton. North American natural gas price was $ US 4.12 per MMBTU at the time of writing in January 2023. At this price, the reduction in fuel consumed would therefore result in a saving of 4.12 x 0.52 = $ 2.14 per ton. For an average size hot strip mill with 4mt / year of output and a hot charging ratio of 50 %, this translates to cost saving of over $ 4 million per annum.

The above decrease in fuel consumption will also reduce CO2 emissions by 27.8 kg per ton of slab hot charged at 700 C.

Note that North American natural gas prices are typically well below those in the EU. Therefore, European steel manufactures will experience substantially greater savings. Erdemir Group in Turkey reported a $ 13 million per year saving achieved between 2011 and 2013 – as a result of hot charging 50 % of its production at an average temperature of 586 C.

Characteristics and Limitations of Gas Fired Reheat Furnaces

Hot rolling mill reheat furnaces do not deliver full benefits from hot charging unless they have long sequences of similar temperature slabs – and the hot mill can roll at an increased level of output matching that of the hot charged furnace. Reheat furnaces are large boxes in which all slabs or billets move simultaneously at the same speed - and experience similar thermal conditions. Differential heating of individual slabs or billets is not possible.

Fig 5: Interior of a hot strip mill reheat furnace.

Furnace control models identify the coldest / slowest slab in the furnace – then set transfer speed for the entire charge based on bringing this one slab or billet to the required rolling temperature. In this scenario, one cold slab prevents every hot charged slab in a furnace from being discharged at the higher rate needed to achieve fuel savings and increased productivity. Because of this feature, small differences in actual operating practice, such as production planning, caster sequence lengths, slab transport, etc. often have a significant impact on hot charging benefits.

Gas fired reheat furnaces are also problematic in several additional ways

- They expose slabs to a hot combustion product atmosphere which is oxidizing towards steel. This results in the formation of an oxide “scale” layer which typically consumes between 0.5 and 1.0 % of the charged slab weight. So, a 4 million ton per year hot rolling mill can potentially loose 40,000 tons per year of slab due to scale formation. There is a relationship between scale generation and furnace residence time, therefore we might expect at least some decrease in this figure as a result of hot charging. Billet rolling operations using 100 % electric induction heating cite virtual elimination of scale losses as a major benefit which they have realized.

- Slabs extracted from gas fired reheat furnaces usually have a far from uniform temperature distribution. The greatest such temperature issue involves skid marks. These are cold transverse bands located where the slab is shadowed by support beams and contacts cold support knuckles. Because cold steel is harder, the skid marks create corresponding bands of increased product thickness – and in extreme cases can also affect mechanical properties.

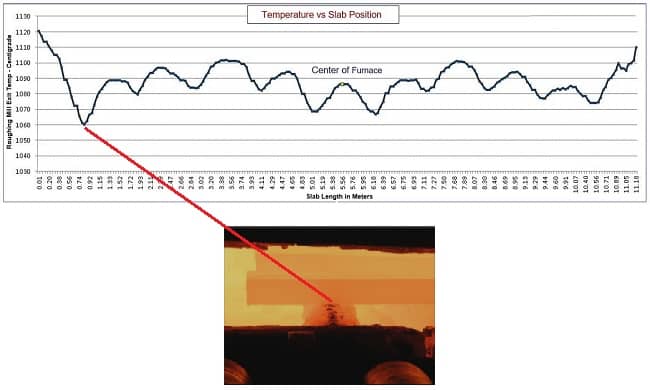

Fig 6: Longitudinal temperature variation after 3 rolling passes. Skid marks from support beams are visible.

In conclusion, gas fired hot mill reheat furnaces are not suitable for hot charging slabs that have a range of incoming temperatures. This is because they cannot adjust heating on a per-slab basis. Under these circumstances, all slabs in the furnace must be produced at a rate and with temperature conditions set for the coldest / slowest slab. Also, gas fired reheat furnaces incur losses due to (oxide) scale formation, and have issues with longitudinal temperature variations within individual slabs. And of course, even when hot charged, they still produce significant amounts of CO2.

Clearly then, reheat process changes are required to maximize hot charging benefits. And at the same time, it is highly desirable for these to also address other issues with scale generation and longitudinal temperature within slabs.

Electric Induction Heating

Induction heating uses coils to induce powerful electric currents – which create resistance heating inside a slab or billet. (This heating is much faster than in a gas fired furnace - which only delivers heat to the steel surface).

When supplied with green electricity, the carbon footprint of induction heating is close to zero. Also, induction heaters are compact and good candidates for retrofitting. Well regarded manufacturers offer induction heating systems for both slabs and billets.

Induction heating also has a fast response and localized application. Because of this, hot strip mills now sometimes use induction heating to remove problematic temperature variations in slabs after they exit the reheat furnace.

Potentially, a retrofitted induction unit could be used to provide variable pre-heat to slabs in front of an already existing gas fired furnace. By ensuring a consistently elevated slab entry temperature, hot charging could be used to full advantage, and furnace output increased to a consistently higher level. In this case however, there would be little if any reduction in scale generation or decrease in skid marks.

Another possibility involves retro-fitting an induction unit after the furnace discharge. This might be used to correct skid marks as well as to adjust bulk temperature to some extent.

Over time, hot strip mills will likely eliminate gas fired reheat furnaces and opt instead for 100 % electric induction heating. Large and powerful heating units will be required to deliver hot slabs at the rate they are consumed by the rolling mill.

100 % induction heating also improves yield by eliminating the thick scale layer that forms on slabs and billets in gas fired reheat furnaces. In a large hot strip mill, this yield loss can be around $ 10 million per year. Additionally, the very high-pressure water sprays required for scale removal from slabs are high maintenance items which consume significant electricity.

Although the authors are not aware of any hot strip mills using 100 % induction re-heating of slabs, 100 % induction re-heating is being used to good effect in billet rolling operations – as is documented in the technical literature.

Next Steps for Your Hot Rolling Operation

The benefit from hot charging a long series of slabs at 700 C can be in the order of:

- A 28 % increase in reheat furnace productivity

- A fuel saving of 0.55 GJ/ ton

- A reduction in CO2 emissions of 27 kg/ton.

Payback on projects that seek to increase hot charging ratios is typically very fast – often one year or less.

If you are seeking to reduce your carbon footprint and improve overall hot rolling efficiency by maximizing your hot charging performance, why not give us a no-obligation call?

Whether you produce flat or long products, our experts will be pleased to discuss your requirements with a view to preparation of an initial concept study.

Our contact number is 0044 775 149 0885 or email us at info@steelonthenet.com

CONSULTING SUPPORT

Looking for consultancy support? We have experts in melting, casting and rolling of steel; and other professionals who specialise in site exploration, geology, mining, beneficiation, and raw material supply.

To contact us about improving your hot charging performance please email info@steelonthenet.com.